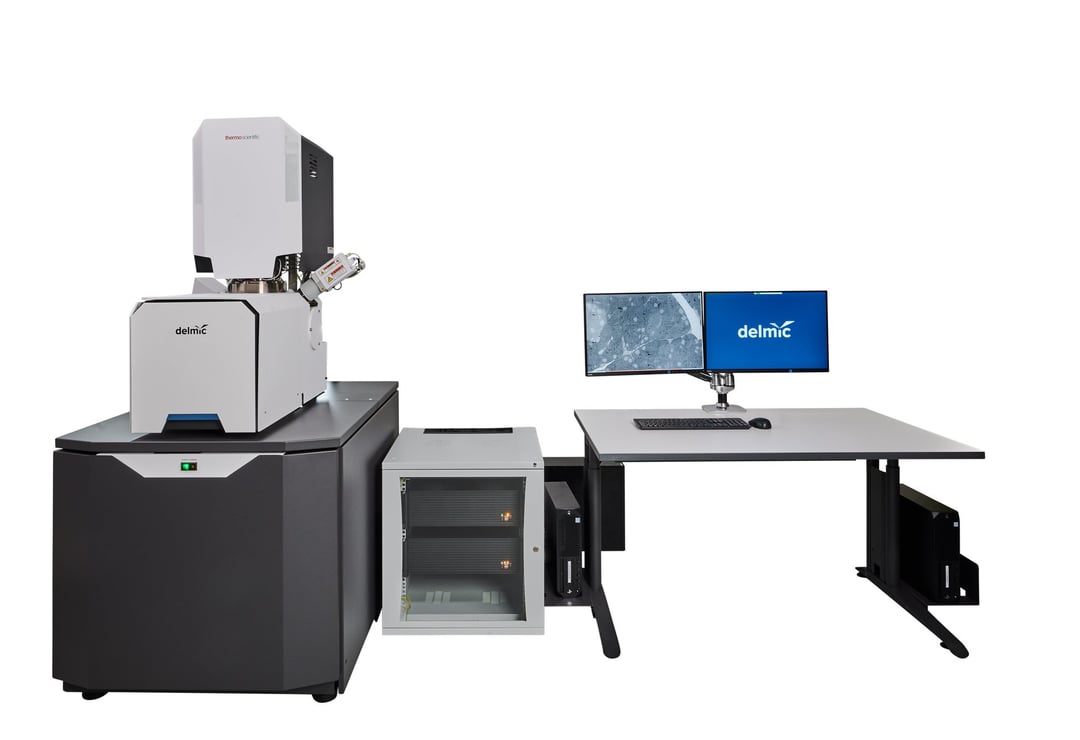

FAST-EM system was created by a consortium, consisting of Delmic, Thermo Fisher, Technolution and Delft University of Technology (TU Delft): each party brought the expertise necessary to develop and build this next generation microscopy system.

STEM image formation

One of the key features that makes such a fast workflow possible, is the detection strategy used in FAST-EM. Instead of detecting secondary or backscattered electrons to create an image of the sample, the system uses Scanning Electron Transmission Microscopy (STEM) for image formation. This is achieved by detecting electrons that pass through the sample with a detector that is located underneath the sample. The sample is placed directly on a scintillator screen, which serves as the sample carrier. Scintillators produce localized cathodoluminescence when struck by electrons, which is captured using optical microscopy, and recorded with a fast and highly sensitive Silicon Photo Multiplier (SiPM) array. The unique detection setup can be used to obtain excellent signal to noise ratios even at shorter dwell times per pixel (the exposure time needed for the electron beam to scan one pixel of the sample) - as short as 400 ns.

64 beams

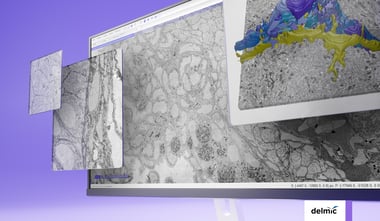

FAST-EM collects data with 64 electron beams simultaneously, which are oriented in an eight-by-eight grid. Each beam scans its own area of 3.2 µm by 3.2 µm from which the signals are collected with the optical STEM detector. The images from each beam are then combined to form a single, seamless image.

Automation software

The automation software used by FAST-EM allows the operator to leave the system working without constant supervision for 72 hours straight. Even at a sustained throughput of 100 MP/s the system stays stable and runs consistently through the whole imaging process. With robust automation and easy-to-use software, projects can be created and managed in a simple manner.

Sample loader

Together with the improved automation, an improved sample exchange process introduced in FAST-EM allows for significant reduction of the overhead of an EM workflow. The system users can load up to nine substrates at the same time, where each substrate can hold tens or even hundreds of sections. This allows for up to 72 hours of continuous imaging.

In September we are hosting a webinar to go over technical aspects of the system in details. Make sure to register if you would like to learn more and ask us your questions.

.png)