Fortunately, automation and its unquestionable benefit of saving time are now becoming available to the EM community. In this blog post, we describe these developments and highlight how they are improving the time- and cost-efficiency of electron microscopy research.

Automation is the use of technology that minimizes human intervention in a process. As per Britannica, "there is scarcely an aspect of modern life that has been unaffected by it" (1). Scientific progress has not only been "affected" by automation, it's been in fact critically dependent on it.

Most of the time, the development of a scientific technique is primarily focused on pushing the physical parameters achieved with the technique, for example, spatial or time resolution or speed. Sooner or later, however, also other aspects start playing an important role, such as time- and cost-efficiency, throughput, and ease of use.

In recent years, EM systems have become more advanced and with the automation of various steps in the EM workflow, the process has been greatly simplified and accelerated. Let's explore which steps are now automated and how this benefits the EM users.

In the process of image collection with EM, the stability of the acquisition parameters can deteriorate over time. This results in images of poor quality and potential further loss of time if the measurements are to be repeated. Therefore, up until recently, EM users have had to continuously monitor the imaging process and intervene if needed. Though in this way the risk of collecting low-quality data can be minimized, it is also putting unnecessary strain on the EM users, taking away the time they could spend on more important tasks. This is one of those perfect case scenarios where automation dramatically changes the user experience. We would like to show how it comes to life on the example of our FAST-EM. Once a user mounts a biological sample onto the system, sets the acquisition parameters and starts a new measurement, the beamlets originating from the electron multibeam that went through the studied material, are partially reflected onto a diagnostic camera. This camera allows the system to monitor the quality of the beamlets. Changes in their features immediately trigger respective, fully automated realignments in the system, restoring the optimum values of acquisition parameters, such as focus and stigmation. As a result, image quality is maintained throughout the entire acquisition time without any intervention of the EM operator who can now focus on the actual challenges in her/his research project.

How long can an acquisition run unsupervised? Check the answer in our FAST-EM brochure.

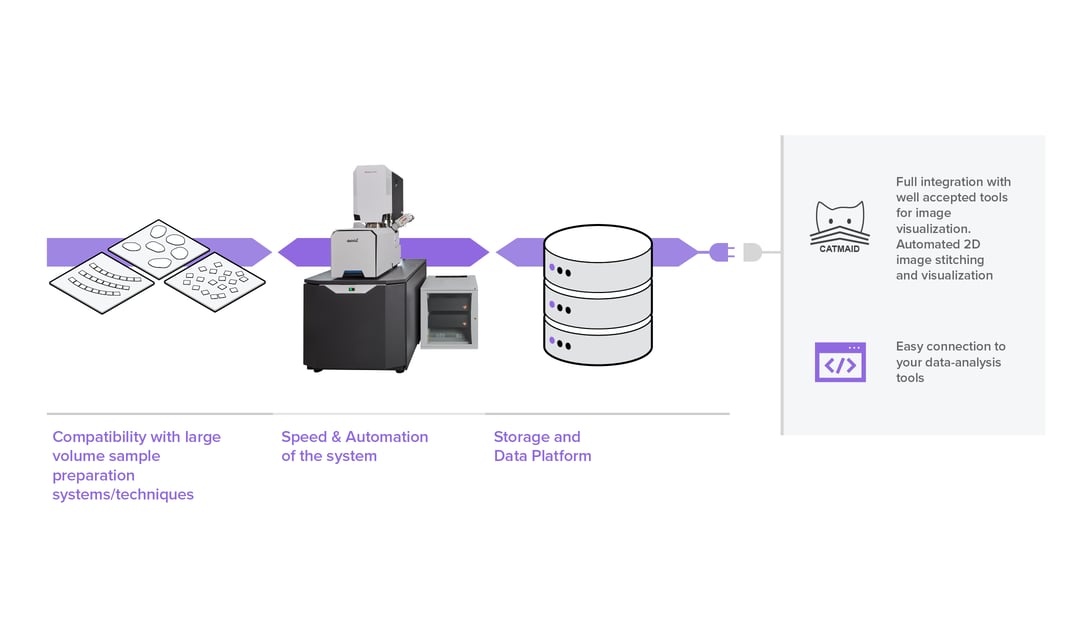

The need to supervise the EM image acquisition process is not the only time sink in the traditional EM workflow. To cover a region of interest, multiple fields of view are typically acquired and subsequently stitched together. This operation would typically be manual, with the use of third-party software. FAST-EM automates the process of stitching the various fields of view together by leveraging its state-of-the-art stage that is controlled and positioned with extremely high accuracy (nm range) via laser interferometry. Already stitched regions of interest are then automatically displayed to the user on visualization tools such as CATMAID.

As a result of the high throughput and high level of automation of FAST-EM, a user saves time and can vacate the system earlier. In imaging facilities, with many users, different samples and tight equipment schedules, this opens an opportunity to accommodate more users and therefore run a system in a much more profitable way.

FAST-EM is at the centre of an innovative, fast, and automated workflow for electron microscopy. It provides unprecedented imaging throughput, thanks to its 64 parallel beams. Further, it provides dedicated processing and storage capabilities that enable the visualization of nanometer-scale details and the context of large fields of view already stitched together, with a simple click. Last, but not least, FAST-EM is compatible with the readily available automated array tomography solutions for sample sectioning and collection, enabling working with either multiple ribbons (see 2) or multiple individual sections (see 3,4).

From sample preparation and collection, through imaging and images visualization and navigation, FAST-EM provides an end-to-end, high-throughout, and automated workflow for electron microscopy.

If you are interested in how we did it and how much faster the complete workflow now gets, check our FAST-EM brochure. Our customers share there also how they are already benefitting from the automation and the high throughput.

References

[1] https://www.britannica.com/technology/automation

[2] ARTOS 3D

[3] MagC

[4] Collectome

.png)