In cryo-ET, the acquisition of fluorescence images, also called cryogenic fluorescence light microscopy (cryo-FLM), enables cryo-ET users to identify the precise location of a region of interest (ROI) within their sample. With this information, they can guide the optimal position for the subsequent lamella milling process and ultimately maximize the probability of acquiring the desired cryo-ET images.

A camera is the last element in the optical path of a cryo-FLM system and its characteristics have a significant impact on the quality of the acquired images. Below, we describe several parameters that have a major effect on this quality.

What affects the signal-to-noise ratio (SNR) and how can you improve it?

Noise is inherent to all electronic image sensors. Its level defines the minimum level of the detectable signal and therefore impacts the sensitivity of a camera. To increase this sensitivity, quantified by a signal-to-noise ratio (SNR), camera producers implement solutions that decrease different types of noise. Let’s review the two major types of noise and the applied countermeasures.

Independently of light, cameras exhibit the so-called dark noise. It is caused by an inherent dark current, meaning electrons that were released in the sensor due to random events at the atomic scale. Fortunately, the number of these unwanted events decreases with the lowering temperature of a camera sensor. This can be achieved by cooling the camera sensor through an internal camera fan or by making use of liquid cooling.

It should be noted that many optical configurations, like super-resolution FLM and lamella milling, are sensitive to the vibrations of the camera fan making liquid cooling the best option. A permanent vacuum can also be created in the chamber with the sensor, thereby assuring its deep cooling.

During a readout process, another type of noise occurs in a camera sensor. It is called 'read noise'. In the modern sCMOS cameras, its level is by default very low. In some cameras, the read noise is further decreased in a process called two-times correlated multisampling (2-CMS). Though the frame rate is lower in the resulting low noise mode, it is still suitable for the fixed cryo-ET samples. The resulting extremely high sensitivity of a camera is suitable especially for cryo-ET samples in which the target macromolecules have not been overexpressed. Without a high SNR, it can be difficult to discern ROI from the background under these native conditions.

What is Quantum Efficiency (QE) and why does it matter?

Another parameter of a camera that influences the quality of the acquired images is quantum efficiency (QE). Digital cameras convert incident photons into electrons and QE is the ratio of the number of input electrons to the number of output photons. An ideal camera would convert all photons into electrons, preserving the complete signal from a sample. In reality, however, no camera reaches 100% QE. With the illumination of a sensor from its back side where more photons can be absorbed, some high-end cameras achieve a remarkable 95% QE.

Why choose a monochrome (black and white) camera for cryo-FLM?

The major difference between a monochrome and a color camera is that the latter has an additional bandpass filter [1]. The absence of this filter in monochrome cameras has several advantages. Firstly, more photons can reach the photosensitive surface of the sensor, resulting in higher QE. Moreover, because there is no interpolation required, the images from monochrome cameras are sharper and have a better resolution than the images from color cameras. Finally, since monochrome image files do not contain specific color channel information, they have a smaller size than the color image files.

Why are pixel size and Nyquist important?

Following the Nyquist criterion, the pixel size of a camera should be two times smaller than the resolution limit at the given wavelength and the numerical aperture of the objective. To resolve the microscopic target macromolecules in a cryo-ET sample, one should therefore pay attention to the pixel size of the cameras used in the cryo-FLM system. The ideal pixel size is when it is small enough to fulfill the Nyquist criterion but not so small that it limits the photon collection capacity per pixel.

When is a high bit depth needed?

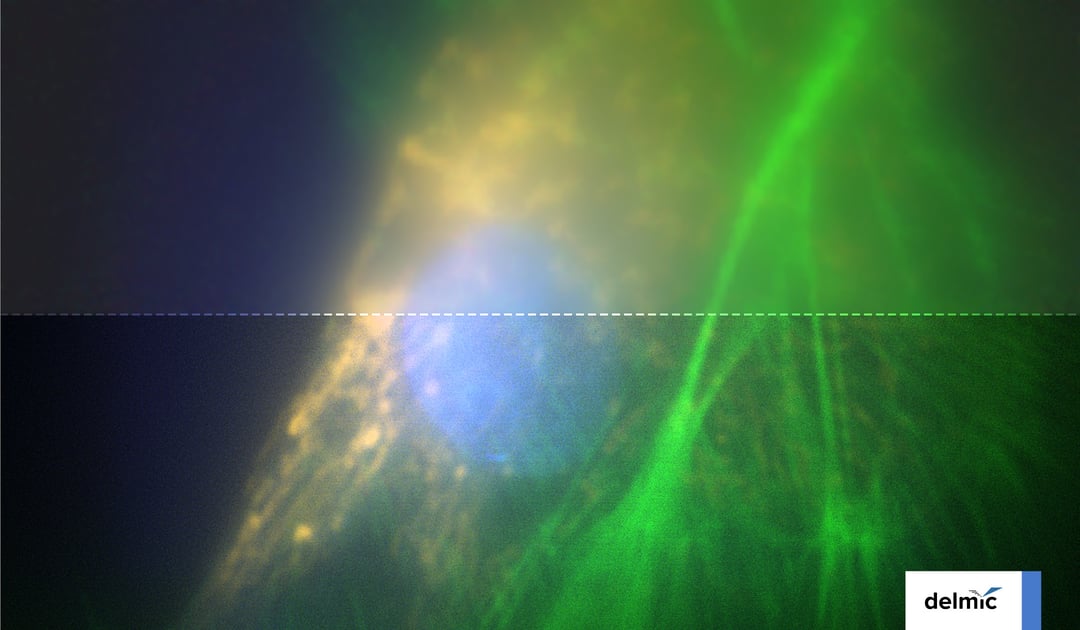

In microscopy, bit depth refers to the binary range of possible grayscale values that can be used. The lower the bit depth, the fewer details can be discerned on an image. In an extreme case, only two colors appear on an image (1-bit): black (background) and white (anything fluorescent above a certain threshold). With a high bit depth, the signal acquired in a camera is spread across a larger range of grey levels and therefore enables revealing structures that have different levels of fluorescence as well as discerning the fluorescent signal of target molecules from auto-fluorescence. A high bit depth is especially important when there is a large variation in fluorescence level, for example between fluorescence signals from the whole cell and from the thin lamella.

Cryo-FLM poses a highly beneficial step in the cryo-ET workflow. To make sure that our cryo-FLM METEOR system fully benefits its users, we carefully considered every element of its design. By reviewing all relevant properties of cameras and their effect on the cryo-FLM images, we selected two high-end cameras to be available for METEOR: Sona 4.2B-6 [2] and Zyla 4.2 [3]. Liquid cooling (Zyla, Sona) and vacuum cooling (Sona) bring the dark noise level in the cameras to an absolute minimum, and the 2-CMS feature in Sona additionally lowers the read noise [4]. Both cameras reach a very high QE of 82% (Zyla) or 95% (Sona). Furthermore, to provide optimal resolution for the typically applied magnifications, while not under-collecting photons, the cameras have a sensor with a 6.5 µm pixel size. Finally, the 16-bit depth in both cameras enables the METEOR users to image all details required for the identification of ROI in their sample.

Overall, these two selected cameras provide cryo-ET researchers with detailed, sharp, high-resolution fluorescence images that correctly guide the subsequent milling process and, as a result, enable obtaining the right lamellas.

References

.png)