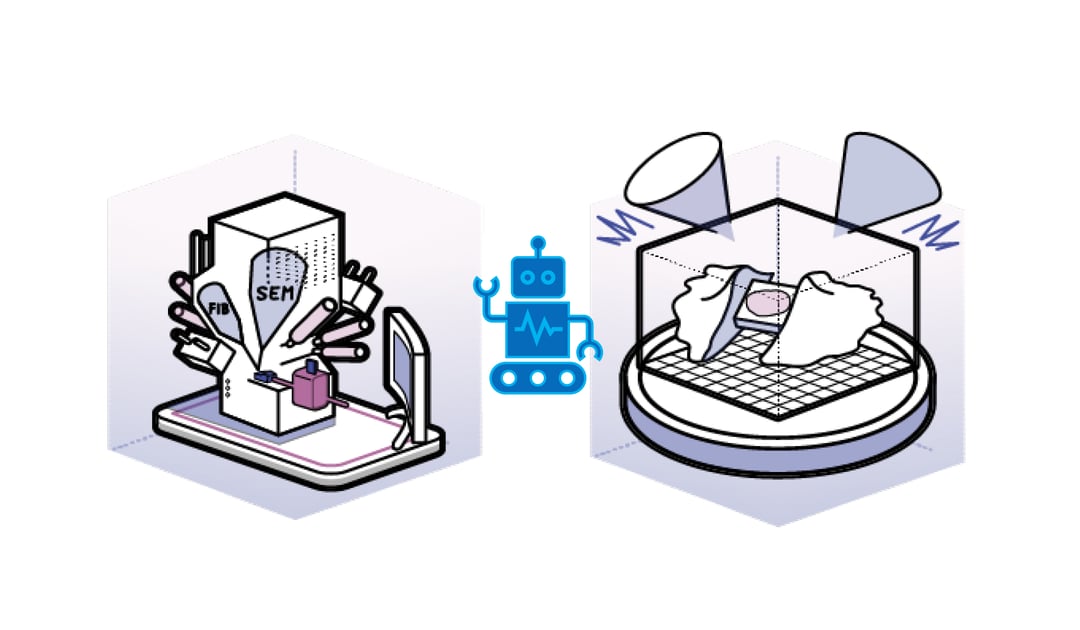

Thicker biological specimens can be studied after thinning with focussed ion beam under cryogenic conditions (cryo-FIB). Unfortunately this is a tedious and time consuming technique and it was reported that only 16 lamellae in a 10 hour session could be created1. As a result, highly trained users are performing an extremely repetitive task and the long operating times are limiting the throughput.

Fortunately, several methods are being developed to automate the milling process and obtain a higher throughput. This year three articles were published describing software applications that automate the key milling steps2–4. The software applications were written for different systems (ZEISS and Thermo Fisher) but employed similar methods. Based on the overview SEM image, the user identifies the regions of interest (ROIs) and sets the relevant input parameters such as milling and imaging current. The software application first performs rough milling on all ROIs and finishes with polishing. This sequence avoids contamination of the final lamellae. The different software applications all resulted in uniform lamellae of desired thickness at a higher throughput showing the potential of automated lamellae milling.

The automated methods were applied to among others yeast cells, cyanobacteria, mammalian cells and microcrystals. The quality of the lamellae was high enough to distinguish structures such as the nuclear pore complex, ribosomes and microtubules in the yeast cells. The septal junctions of the cyanobacteria could also be visualized and by employing subtomogram averaging it could be resolved to a high resolution2.

Currently the duration of a milling session is limited by the liquid nitrogen supply, typically stages can be kept cool for approximately 11 hours before running out of liquid nitrogen. Another limiting factor is condensation inside the FIB/SEM that contaminates the sample. Ideally the sample is kept inside the FIB/SEM as short as possible and the polishing step should be finished within an hour after polishing the first lamella to avoid contamination of the lamellae. If these challenges could be overcome, overnight sessions could become a possibility and open up more machine time for other users. It would also be advantageous if the ROIs could be (automatically) selected based on a fluorescent light microscopy (FLM) image. This would allow creation of lamellae that include rare events that can only be captured using FLM.

Automated lamellae milling can increase the throughput of the FIB/SEM allowing more research projects to run in parallel and freeing up time of researchers to perform other experiments. Moreover, projects that are currently not feasible due to the challenges in obtaining a high amount of lamellae could become a possibility.

References

[1] Medeiros, J. M. et al. Robust workflow and instrumentation for cryo-focused ion beam milling of samples for electron cryotomography. Ultramicroscopy 190, 1–11 (2018).

[2] Zachs, T. et al. Fully automated, sequential focused ion beam milling for cryo-electron tomography. eLife 9, 1–14 (2020).

[3] Buckley, G. et al. Automated cryo-lamella preparation for high-throughput in-situ structural biology. Journal of Structural Biology (2020) doi:10.1016/j.jsb.2020.107488.

[4] Tacke, S. et al. A streamlined workflow for automated cryo focused ion beam milling. bioRxiv 2020.02.24.963033 (2020) doi:10.1101/2020.02.24.963033.

This work is supported by the European SME2 grant № 879673 - Cryo-SECOM Workflow

.png)