In recent years the technique has gained popularity and an increasing number of research groups are implementing it in their lab. Cryo-ET was already used to gain valuable insights in research areas such as virology and neurobiology.

The power of cryo-ET is undisputed but the fact that the workflow is very error-prone has limited the number of high-quality publications. In the workflow, there are two main challenges: keeping the sample ice contamination-free and targeting the region of interest (ROI). Have you thought about how these challenges can be overcome?

At Delmic we are dedicated to making microscopy an easy and accessible technique so that researchers can focus on the research question at hand and not on the instrument. That is why we developed two workflow solutions called CERES and METEOR to streamline the entire cryo-ET preparation workflow. The CERES Ice Defence System consists of multiple innovative tools that are tailored to minimize ice contamination at the different steps of the workflow. METEOR is the first commercially available integrated fluorescence light microscope (FLM) that greatly enhances the ROI targeting inside the cryo-FIB/SEM while reducing the number of handling steps required. Using both CERES and METEOR will drastically increase the amount of high-quality cryo-ET data and make the entire workflow more efficient.

An example of a typical sample preparation workflow using both CERES and METEOR tools is described below:

After the sample is vitrified the user will transfer the sample to the CERES Clean Station which provides a clean and moisture-free environment for the next preparation steps. The anhydrous environment allows the user to completely focus on the task at hand: clipping the sample and placing it in the shuttle without having to worry about moisture in the environment or feel rushed completing this task. Once the sample has been prepared it can be transferred to the cryo-FIB/SEM using the CERES Vitri-Lock providing a high vacuum, anhydrous environment. It enables a safe transfer time of up to 30 minutes by active cooling of the sample, allowing the user to safely transfer the sample without making hasty mistakes. Once the sample is transferred in the cryo-FIB/SEM the user can relax, knowing that their samples will be maximally protected from ice contamination by the CERES Ice Shield, which protects against amorphous ice build-up on the sample whilst in the vacuum chamber. This protection is crucial for high cryo-ET data quality.

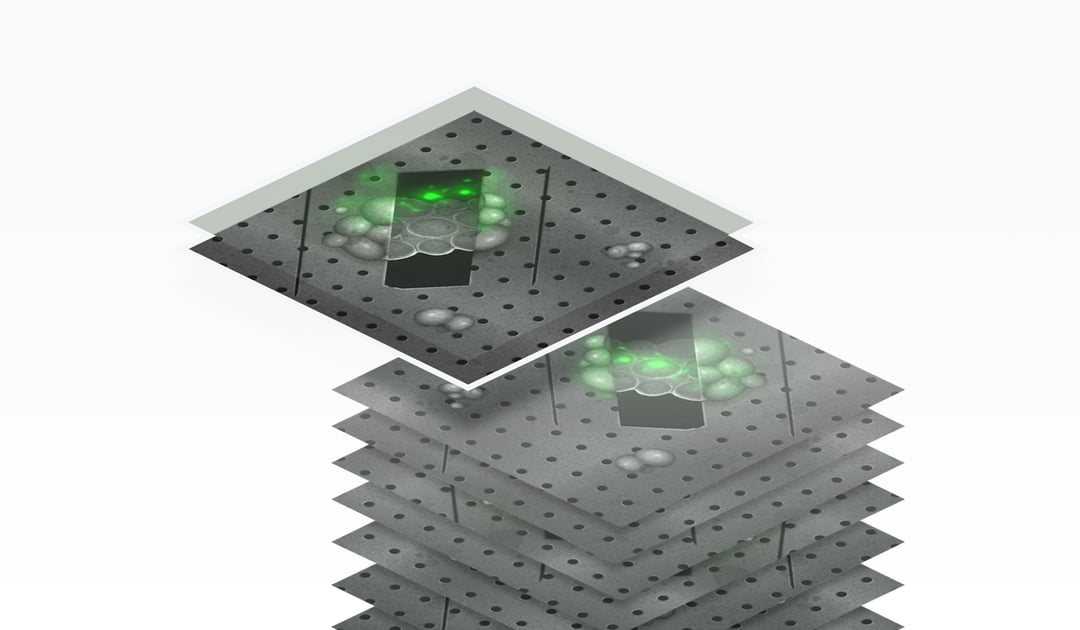

Before starting lamella milling, the sample can be imaged using METEOR to find the ROIs. Since METEOR is directly integrated into the cryo-FIB/SEM the user can skip the time consuming and error-prone steps associated with using a separate cryo-FLM. During the milling, the fluorescence from the lamella can be checked with METEOR to ensure the current milling strategy is capturing the ROI in the lamella. After milling a final inspection can be performed to confirm that the ROI is indeed inside the lamella.

Once the user has finished milling all the lamellae the sample can be transferred out of the cryo-FIB/SEM using the CERES Vitri-Lock and placed into the TEM cassette in the CERES Clean Station. Using both these devices will ensure that the precious lamellae will stay frost free. Once the sample is transferred to the cryo-TEM the user can start acquiring high-quality data from lamellae that contain the ROI and are ice contamination-free.

What does Delmic hope to achieve by making METEOR and CERES commercially available to the cryo-ET community? By streamlining the entire workflow using METEOR and CERES researchers can focus on obtaining more data and getting insights into highly relevant biological processes. It will also allow the technique to be taken up by more labs with inexperienced users making this powerful technique more accessible.

This work is supported by the European SME2 grant № 879673 - Cryo-SECOM Workflow.

.png)